| OVERVIEW: | |||

| Dispersers are highly efficient dispersing and mixing machines that have been employed in several industries across the globe. Their sheer performance garner immense demand for the Dispersers. Renders manufacture, market and export the SmartMix Disperser series. Our SmartMix Dispersers are designed for premixing, mixing, dispersing. The Disperser achieves particle size reduction by breaking up materials i.e. solid particles which need to be sheared mixed homogeneously with the base fluid. In case of mixing of two or more liquids with similar or dissimilar properties, our SmartMix Disperser series emulsifies, blends or mixes with high efficiency. Dispersers don’t grind but they help in breaking down of solid agglomerates as found in paints, inks chemicals, pigment, etc. during the mixing and also dispersing the reduced sized particles evenly in the base liquid.

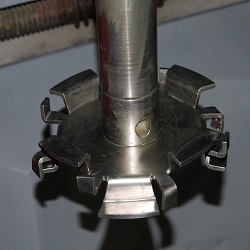

The Single Shaft Disperser has a single shaft with a dispersion blade attached to it. |

|||

SALIENT FEATURES

- Designed to perform, designed for excellence SmartMix Single Shaft Dispersers perform premixing, mixing, dissolving, blending, dispersing, homogenizing and shearing.

- Apart from mixing, particle size reduction and dispersion are the advantages that make these machines inevitable for many process managers.

- Available in wide range of capacities from small scale to large production scale. Various vessel capacities configurations available to suit process requirements ranging from 1 L to 2000 L and beyond.

- SmartMix Single Shaft Dispersers are manufactured with variety of materials of construction that may include Mild Steel (MS), Stainless Steel (SS) of all grades and several other materials to suit your process requirements best. Construction materials are suitable for strong abrasive and corrosion resistance.

- The vessel is available in jacketed versions for cooling or heating purpose and provisions of necessary inlet and outlet with nozzles bring about perfect process environment for the Single Shaft Disperser.

- It has hydraulic lifting and lowering arrangement by virtue of which we can move or change the vessel easily. The hydraulic arrangement also enables us to process multiple type of batches in the SmartMix Disperser without contamination in the final product.

- Our disperser is vacuumable. Thus it servers the exact vacuum process requirement of many industries.

- A perfect operating speed ranging from 10 to 2880 revolutions per minute (RPM) to suit your requirement is achieved by combining of superior quality Motor, VFD (Variable Frequency Drive) and other electro-mechanical arrangements.

- Our precisely calculated torque, revolutions of shafts, type and dimensions impellers or blades, dimension of shaft, sealing system etc. make our SmartMix Single Shaft Disperser give unmatched quality and superior performance.

- All our SmartMix models are safe, as we offer every product in certified explosion proof options.

- It has brilliant option of quickly and easily interchangeable impellers/blades for mixing and dispersing of different applications.

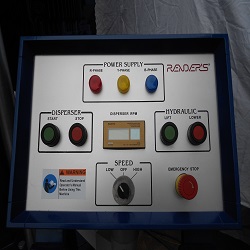

- The SmartMix Single Shaft Disperser may combine with smart features that include speed controller, temperature and pressure monitoring devices, programmable logic controller (PLC) ,HMI control panel, touch panels, limit switches, sensors, auto-valves and several other highly advanced features and process automation provisions to make your entire set of machinery and process ‘smarter’.

- SmartMix Single Shaft Dispersers are painted and coated superiorly for great aesthetic looks and long life span. A supreme finishing touch of the wetted parts i.e. buffing, polishing etc. give the machines unmatched look.

- Finished material discharge is through valves or manually by movable tanks.

- The SmartMix machines generate unbelievably low noise during operation thus reducing the sound pollution.

- Our SmartMix Dispersers are well capable of handling low to medium viscous materials, thus it proves to be extremely efficient in dispersing and mixing technologies.

- The Disperser is equipped with provisions for easy and convenient cleaning to avoid any possible contaminations.

- Vessel locking by arms and its integration with the operation a by limit switch, automatic lifting up and lowering down, dust proof tank cover, vortex cutter, fume collector etc are some compelling features of our SmartMix Dispersers that positions our machines stand out of the contemporary competition.

- Some other features are: Digital Energy Meter, Digital Temperature Indicator, Hooter System, MCCB, SMPS, Drag Chain etc.

SPECIFICATION

| Product Code / Model No. | Tank / Full Cap. [Lit] | Working / Batch Cap. [Lit] | Disperser Motor (Rating) HP | Disperser Shaft Highest RPM | Blade Specification | Hyd. Motor HP | Lifting & Lowering Arrangement | |

| SMARTMIX SSD-AF-50 | 65 | 50 | 2 | 1440/2800 | Saw Tooth or Cowles | 1 | Hydraulic Operated | |

| SMARTMIX SSD-AF-100 | 125 | 100 | 3 | 1440/2800 | Saw Tooth or Cowles | 1 | Hydraulic Operated | |

| SMARTMIX SSD-AF-200 | 250 | 200 | 7.5 | 1440/2800 | Saw Tooth or Cowles | 1.5 | Hydraulic Operated | |

| SMARTMIX SSD-AF-500 | 625 | 500 | 10 | 1440/2800 | Saw Tooth or Cowles | 1.5 | Hydraulic Operated | |

| SMARTMIX SSD-AF-800 | 1000 | 800 | 15 | 1440/2800 | Saw Tooth or Cowles | 2 | Hydraulic Operated | |

| SMARTMIX SSD-AF-1000 | 1250 | 1000 | 25 | 1440/2800 | Saw Tooth or Cowles | 3 | Hydraulic Operated | |

| SMARTMIX SSD-AF-1500 | 1800 | 1500 | 40 | 1440/2800 | Saw Tooth or Cowles | 3 | Hydraulic Operated | |

| SMARTMIX SSD-AF-2000 | 2400 | 2000 | 50 | 1440/2800 | Saw Tooth or Cowles | 3 | Hydraulic Operated | |

| If any special requirement regarding above product pls. give the detail to fulfill your requirement. | ||||||||

USES & APPLICATIONS

- Paints

- Marine Paint

- Wood Paint / Varnish

- Top Coat

- Road Marking Paint

- Fillers

- Clear Coat

- Cathodic Dip Coating

- Coil Coating

- Construction Paint

- Industrial Coating

- Aerospace Paints

- Wood Coating

- Decorative Coating

- Polyurethane Coating

- Additives

- Automotive Paint

- Pigments / Dyes

- Pigment Production

- Printing Inks

- Screen Printing Inks

- Chemicals

- Pharmaceuticals

- Food processing industries

- Adhesives and Glues

- Inks

- Agrochemicals

- Beverages

- Creams

- Compounds

- Cleaning products

- Dispersions

- Coatings

- Pigments

- Colorants

- Cosmetics

- Enamels

- Confectionary

- Microbiological products

- Lubricant Additives

- Paper coatings

- Pharmaceuticals

- Emulsions

- Lipstick mixtures

- Lotions,

- Pill coatings

- Polyesters,

- Rubber

- Resins

- Ceramics

- Marine coating

- Dyestuff

- Textiles

- Plasters

- Polymers

- Wood coatings

- Floor Coatings

- Colorants

- Syrups

- Shampoo

- Wall-paints

- Wax emulsions

- Water/oil emulsions

- Water-treatment

RENDERS ADVANTAGES

- Our SmartMix Single Shaft Disperser is compact designed thus occupying very less space.

- The SmartMix Single Shaft Dispersers are very cost effective, energy efficient and thus are economical in operation.

- Superior materials, components used to construct our SmartMix Single Shaft Dispersers impart maximum durability with sturdy and robust characteristics.

- Our aim of ‘guaranteed satisfaction’ is achieved by fully customized design for small tank capacities to large tank capacities for various viscosity ranges and customization of other components including material of construction, impellers and other features according to the customers’ need.

- We design and manufacture SmartMix Single Shaft Dispersers with latest industry standards and comply with international standards of engineering.

- Our SmartMix Single Shaft Dispersers are configured and manufactured of high grade components like motor, belts, bearings, and seals etc .improves quality of the machine.

- Our machines are safe, easy and convenient in operation without any hassles.

- Renders SmartMix Advanced Featured (AF) Single Shaft Dispersers possess all advanced features that you wish to possess i.e. speed control, pressure monitoring and control, temperature monitoring and control, HMI Control panels, process automation by limit switches, auto control valves, load cells, ultra sonic sensors, etc.

- Easy available of spare parts or wear and tear parts

- Short manufacturing and delivery time.